Order Now

- Home

- About Us

-

Services

-

Assignment Writing

-

Academic Writing Services

- HND Assignment Help

- SPSS Assignment Help

- College Assignment Help

- Writing Assignment for University

- Urgent Assignment Help

- Architecture Assignment Help

- Total Assignment Help

- All Assignment Help

- My Assignment Help

- Student Assignment Help

- Instant Assignment Help

- Cheap Assignment Help

- Global Assignment Help

- Write My Assignment

- Do My Assignment

- Solve My Assignment

- Make My Assignment

- Pay for Assignment Help

-

Management

- Management Assignment Help

- Business Management Assignment Help

- Financial Management Assignment Help

- Project Management Assignment Help

- Supply Chain Management Assignment Help

- Operations Management Assignment Help

- Risk Management Assignment Help

- Strategic Management Assignment Help

- Logistics Management Assignment Help

- Global Business Strategy Assignment Help

- Consumer Behavior Assignment Help

- MBA Assignment Help

- Portfolio Management Assignment Help

- Change Management Assignment Help

- Hospitality Management Assignment Help

- Healthcare Management Assignment Help

- Investment Management Assignment Help

- Market Analysis Assignment Help

- Corporate Strategy Assignment Help

- Conflict Management Assignment Help

- Marketing Management Assignment Help

- Strategic Marketing Assignment Help

- CRM Assignment Help

- Marketing Research Assignment Help

- Human Resource Assignment Help

- Business Assignment Help

- Business Development Assignment Help

- Business Statistics Assignment Help

- Business Ethics Assignment Help

- 4p of Marketing Assignment Help

- Pricing Strategy Assignment Help

- Nursing

-

Finance

- Finance Assignment Help

- Do My Finance Assignment For Me

- Financial Accounting Assignment Help

- Behavioral Finance Assignment Help

- Finance Planning Assignment Help

- Personal Finance Assignment Help

- Financial Services Assignment Help

- Forex Assignment Help

- Financial Statement Analysis Assignment Help

- Capital Budgeting Assignment Help

- Financial Reporting Assignment Help

- International Finance Assignment Help

- Business Finance Assignment Help

- Corporate Finance Assignment Help

-

Accounting

- Accounting Assignment Help

- Managerial Accounting Assignment Help

- Taxation Accounting Assignment Help

- Perdisco Assignment Help

- Solve My Accounting Paper

- Business Accounting Assignment Help

- Cost Accounting Assignment Help

- Taxation Assignment Help

- Activity Based Accounting Assignment Help

- Tax Accounting Assignment Help

- Financial Accounting Theory Assignment Help

-

Computer Science and IT

- Operating System Assignment Help

- Data mining Assignment Help

- Robotics Assignment Help

- Computer Network Assignment Help

- Database Assignment Help

- IT Management Assignment Help

- Network Topology Assignment Help

- Data Structure Assignment Help

- Business Intelligence Assignment Help

- Data Flow Diagram Assignment Help

- UML Diagram Assignment Help

- R Studio Assignment Help

-

Law

- Law Assignment Help

- Business Law Assignment Help

- Contract Law Assignment Help

- Tort Law Assignment Help

- Social Media Law Assignment Help

- Criminal Law Assignment Help

- Employment Law Assignment Help

- Taxation Law Assignment Help

- Commercial Law Assignment Help

- Constitutional Law Assignment Help

- Corporate Governance Law Assignment Help

- Environmental Law Assignment Help

- Criminology Assignment Help

- Company Law Assignment Help

- Human Rights Law Assignment Help

- Evidence Law Assignment Help

- Administrative Law Assignment Help

- Enterprise Law Assignment Help

- Migration Law Assignment Help

- Communication Law Assignment Help

- Law and Ethics Assignment Help

- Consumer Law Assignment Help

- Science

- Biology

- Engineering

-

Humanities

- Humanities Assignment Help

- Sociology Assignment Help

- Philosophy Assignment Help

- English Assignment Help

- Geography Assignment Help

- Agroecology Assignment Help

- Psychology Assignment Help

- Social Science Assignment Help

- Public Relations Assignment Help

- Political Science Assignment Help

- Mass Communication Assignment Help

- History Assignment Help

- Cookery Assignment Help

- Auditing

- Mathematics

-

Economics

- Economics Assignment Help

- Managerial Economics Assignment Help

- Econometrics Assignment Help

- Microeconomics Assignment Help

- Business Economics Assignment Help

- Marketing Plan Assignment Help

- Demand Supply Assignment Help

- Comparative Analysis Assignment Help

- Health Economics Assignment Help

- Macroeconomics Assignment Help

- Political Economics Assignment Help

- International Economics Assignments Help

-

Academic Writing Services

-

Essay Writing

- Essay Help

- Essay Writing Help

- Essay Help Online

- Online Custom Essay Help

- Descriptive Essay Help

- Help With MBA Essays

- Essay Writing Service

- Essay Writer For Australia

- Essay Outline Help

- illustration Essay Help

- Response Essay Writing Help

- Professional Essay Writers

- Custom Essay Help

- English Essay Writing Help

- Essay Homework Help

- Literature Essay Help

- Scholarship Essay Help

- Research Essay Help

- History Essay Help

- MBA Essay Help

- Plagiarism Free Essays

- Writing Essay Papers

- Write My Essay Help

- Need Help Writing Essay

- Help Writing Scholarship Essay

- Help Writing a Narrative Essay

- Best Essay Writing Service Canada

-

Dissertation

- Biology Dissertation Help

- Academic Dissertation Help

- Nursing Dissertation Help

- Dissertation Help Online

- MATLAB Dissertation Help

- Doctoral Dissertation Help

- Geography Dissertation Help

- Architecture Dissertation Help

- Statistics Dissertation Help

- Sociology Dissertation Help

- English Dissertation Help

- Law Dissertation Help

- Dissertation Proofreading Services

- Cheap Dissertation Help

- Dissertation Writing Help

- Marketing Dissertation Help

- Programming

-

Case Study

- Write Case Study For Me

- Business Law Case Study Help

- Civil Law Case Study Help

- Marketing Case Study Help

- Nursing Case Study Help

- Case Study Writing Services

- History Case Study help

- Amazon Case Study Help

- Apple Case Study Help

- Case Study Assignment Help

- ZARA Case Study Assignment Help

- IKEA Case Study Assignment Help

- Zappos Case Study Assignment Help

- Tesla Case Study Assignment Help

- Flipkart Case Study Assignment Help

- Contract Law Case Study Assignments Help

- Business Ethics Case Study Assignment Help

- Nike SWOT Analysis Case Study Assignment Help

- Coursework

- Thesis Writing

- CDR

- Research

-

Assignment Writing

-

Resources

- Referencing Guidelines

-

Universities

-

Australia

- Asia Pacific International College Assignment Help

- Macquarie University Assignment Help

- Rhodes College Assignment Help

- APIC University Assignment Help

- Torrens University Assignment Help

- Kaplan University Assignment Help

- Holmes University Assignment Help

- Griffith University Assignment Help

- VIT University Assignment Help

- CQ University Assignment Help

-

Australia

- Experts

- Free Sample

- Testimonial

BE275 Global Supply Chain and Operations Management Assignment Sample

1. Coursework: An Individual Report or Essay (100 % of the total mark).

You are expected to write a report of 3,000 words (including Introduction, Main Body and Conclusion; excluding Executive summary, Tables, Figures, Bibliography and Appendices) on the Topic identified in Section 2, which will assess the knowledge gained throughout the autumn term.

2. Topic: You are required to prepare a report, which will focus on analysis and discussion of INDUSTRY 4.0 and its impact on Operations and Supply Chain.

Background

INDUSTRY 4.0 and its impact on Operations and Supply Chain.

• Industry 4.0 implies a new industrial revolution, combining advanced production and operations techniques with smart technologies that will be integrated into organizations, people and assets. This revolution is marked by the appearance of new technologies such as robotics, analytics, artificial intelligence, cognitive technologies, nanotechnology and the Internet of Things (IoT), among others. Organizations must identify the technologies that best meet their needs in order to invest in them. Thus, Industry 4.0 understand the range of new technologies that appear with this revolution such as: MES Systems (Manufacturing Execution Systems), MOM Systems (Manufacturing Operation Management), Advanced Analytics, Artificial Intelligence (AI), Collaborative Robotics, Industrial Internet of Things (IIoT), Big Data, among many others.

• The impacts of Industry 4.0 can be felt on multiple levels, for example in the business ecosystem. In addition to the change in which companies operate and in the production of goods, Industry 4.0 affects all agents of the ecosystem (suppliers, customers, regulatory considerations, investors, third parties ...). Therefore, we can expect this to affect the operations and supply chain in the companies.

• Guiding questions:

• How can Industry 4.0 influence the supply chain?

• How can Industry 4.0 influence operations management in the company?

• How can Industry 4.0 influence organizations?

• How can Industry 4.0 influence people in the company?

Solution

Executive Summary

• The digitization of every industrial activity is at the heart of Industry 4.0. For example, the internet of things (IoT), artificial intelligence (AI), cloud computing (3D printing and blockchain), robotics and automation (RA) as well as big data and analytics (BI) all play a role in this new system.

• With the aid of Industry 4.0, the supply chain of a firm may be digitalized so that it can link different components of the supply chain together in a good supply chain process. An integrated digital supply chain may lower operating costs by about 30 percent, according to research.

• It will also help to cut down on sales chances squandered by around 60%. Around 70% of the inventory needs may be reduced by improved inventory management by the firms. In the long run, Industry 4.0 is good for businesses because it helps them become more efficient, nimble, and accurate.

Introduction

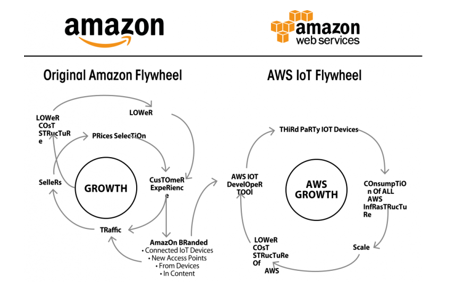

An industry's operations must be digitalized in order to achieve Industry 4.0's goal. The “internet of things (IoT), artificial intelligence (AI), cloud computing, 3D printing, blockchain, robots and automation, big data and analytics, machine learnings”, etc. are some of the technical breakthroughs that make up this new industry (Ghadge et al., 2020). Supply chain information may be digitally recorded in order to tie different components of the supply chain together in a good supply chain process, thanks to Industry 4.0's ability to digitise it. Using a digitally regulated supply chain may lower operating costs by 30 percent, according to research. As a bonus, it'll cut the number of sales chances squandered by 60 percent. Improved inventory management may cut inventory needs by 70% or more for most businesses (Hahn, 2020). Companies benefit from Industry 4.0 because it increases their operational efficiency, agility, and precision. Founded in 1994 by Jeff Bezos in Seattle, Amazon provides cloud computing and e-commerce services, as well as a wide range of other services. If you look at the company's market capitalization and revenue, it is the world's second-largest online retailer behind the Alibaba Corporation. Amazon.com began off as an online book retailer in the early days of its existence. While initially focusing on goods, the firm has steadily expanded into music and video distribution and cloud computing infrastructure services.

Main Body

The firm has been able to become a leader in online retailing because to its extensive use of cutting-edge technology and first-rate operational and supply chain management practises. In 2018, Jeff Bezos was indeed the world's wealthiest man with a market value of $702 billion (Fatorachian & Kazemi, 2021). The firm has also expanded into brick-and-mortar retailing with the purchase of whole foods, which helps to support the company's huge business. This success is credited to the company's use of cutting-edge technology, as well as to its efficient operations and supply chain management.

Figure 1: Supply chain management of Industry 4.0

(Source: semanticscholar.org, 2019)

Industry 4.0 Influence The Supply Chain

The industry has grown rapidly in recent years due to advancements in technology. The internet has had a major impact on the modern-day business world, making it more efficient and accurate. The phrase supply chain 4.0 has been created as a result of the introduction of the concept of Industry 4.0. Just an example of how Industry 4.0 technology may be used in practise. As a consequence of this programme, all supply chain activities have been digitised and made more flexible and efficient. Networking each and every part of the manufacturing process together is beneficial to the firm. The United States government proposed the notion of Industry 4.0 for the first time in 2017 (Szozda, 2017). Companies must incorporate internet and technology into their operations in order to produce a more efficient operating process, according to the principles of Industry 4.0. In order to maximise the benefits, organisations might adapt their production methods. To minimise labour expenses, corporations are using robotics and machine intelligence.

In the beginning, other companies used it to automate their own operations. German enterprises have found it to be a successful approach. There are numerous firms throughout the world that now apply Industry 4.0 concepts in order to completely automate the operational process. Prior to this decade, eBay had established itself as one of the leading e-commerce platforms. It offers a diverse range of products from merchants in a variety of geographical locations. However, according to sources, it is not doing effectively as a result of a lack of adequate supply chain management practises. Over the last several months, eBay has begun integrating the ideas of Industry 4.0 itself into supply chain. The company's long-term objective is to establish a fully automated supply chain (Ivanov, Dolgui & Sokolov, 2019). In recent studies, it has been said that advancements in Amazon's supply chain are favourable to the corporation. Revenues increased by around 30%, and the company has implemented a completely autonomous supply chain system.

Figure 2: Revolution of industry

(Source: datexcorp.com, 2018)

Amazon Supply Chain Developments

Founded in 1994, the company started with two fulfilment centres, one in Seattle and another in Darlington (North Carolina), both having a total floor space of 18,766 square feet. This retail company employs human storage and receiving in the same manner as its retailing competitors, and its clients get their orders within one to seven days, depending on how far they reside and what they purchase. Following that, in 1999, the company expanded its global reach by constructing five other warehouses in various European nations in an attempt to broaden its regional coverage. Following the introduction of the FBA (Fulfillment by Amazon) platform in 2006, Amazon's third-party merchants were able to transmit their products and services directly to Amazon's customers while still maintaining control over their inventory levels on the Amazon platform. The firm would be able to afford the expenses of packing and shipping in the future if this were to happen in the future. After that, in 2013, Jeff Bezos developed a drone delivery system called The Prime Air, which could deliver items in as little as thirty minutes in certain instances (Manavalan & Jayakrishna, 2019). A worldwide logistics provider provider, Amazon established the Global Supply Chain by Amazon in 2016. The Global Supply Chain by Amazon intends to centralise all of Amazon's service offerings around the globe. As a result, consumers would be able to order directly from the firm and have their purchases transported straight to them. As a result, the logistics expenses associated with the intermediaries will be decreased as a result of this. During the year 2017, Amazon purchased Whole Foods in an effort to expand its operations and increase the number of locations it had at its disposal.

Industry 4.0 influence operations management in Amazon

Procurement

In the course of purchasing products and services, Amazon.com takes into account a range of shipping alternatives. It is possible for organisations to purchase goods directly from first-party vendors. Amazon will be allowed to resell the goods to consumers as their own after they have been sold to the company. While being both a merchant and a record owner, here it performs both roles. This procedure is launched by Amazon, which places electronic purchase requisitions and sends them to the appropriate manufacturers in order for the firm to get the different items. After the items have been received by the manufacturing business, they will be sent to one of the 122 facilities that are currently in operation (Dev, Shankar & Qaiser, 2020). A typical week would consist of Monday being the day that the procedure is started.

Also there are second- or third vendors that collaborate with the organisation and contribute to the spread of goods and services for the organisation as a whole. As an example, if we consider second-party sellers, these are businesses that acquire goods directly from manufacturers and then operate as intermediaries by selling products to the Amazon Corporation. Even if they don't deal with the firm that makes the items or provides the services directly, the business ultimately serves as a MOR in this situation. These are businesses that exclusively utilised Amazon.com as a supply of market for their products in the case of direct sellers. Third-party organisations will be able to expand their consumer base as a result of their brand recognition and confidence in Amazon.com as a result of the marketplace they have earned.

It is up to the vendor central to handle the ordering application procedure for third-party vendors, who may then download purchases in the form of PDFs and Excels. When suppliers obtain reference number for their orders after submitting them to vendor central, they follow up with the customers and subsequently publish their bills on the vendor's website. Following the filing of invoices, providers may expect to receive payment in a period ranging between 90 and 120 days (Abdirad, & Krishnan, 2021). The supplier central system developed by Amazon is very important since it is far more efficient than the systems used by other bricks - and - mortar businesses, which depend on methods such as the mail, which are notoriously sluggish to deliver orders.

Warehousing and distribution facilities

The industry's 121 warehouses are used as temporary storage facilities for the company's purchased goods until they are delivered to their respective clients. Customers may expect to find a wide variety of items in the company's warehouses strategically located in crowded hubs, particularly in metropolitan areas. Among them are 32 outward sortation centres, eight incoming sortation centres, and 71 Amazon Flex service delivery locations. The warehouse's activities begin with the sortation of incoming goods at the inbound sortation facilities. Imported goods are the most common focus of this process. The next step is to ship them to fulfilment centres. Locally created items are often sent directly to fulfilment centres.

Inside of "Amazon's warehouses," fulfilment centres are tasked with selecting, packaging, and shipping products. According on the kind and size of the goods, fulfilment centres might vary widely. Fulfillment centres exist in a wide range of sizes and configurations, including large sortable, small sortable, and large non-sortable (Ghadge et al., 2020). The IND5 fulfilment centre in Indiana deals with hazardous products, while the "Arizona PHX3 facility in Phoenix" is in charge of footwear and clothing, among other things.

Figure 3: Digital Transformation of industry 4.0

(Source: electronicsforu.com, 2020)

Product handling in these storage facilities has been made easier thanks to the use of advanced technology. Belt conveyors are among the most prevalent options. Technology has been a crucial factor in Amazon's success in the warehouses. As recently as 2015, Amazons robots were renamed Kiva systems, which the business first debuted in 2012. The products in the warehouses may be chosen and packaged by robots without the assistance of humans, allowing for a far faster turnaround time. More than 45,000 robots were in use at the company's offices as of 2017. Amazons have the most advanced technology in the market. When it comes to keeping groceries and fresh food in stock, whole foods have played a major role.

Additionally, the corporation has outbound sortation centres that aid in the preparation of the packaged and ready items for delivery (Ivanov & Dolgui, 2020). In order to avoid problems, such as long delays and hefty costs, the corporation might use these centres to determine the optimal route of transportation for its goods. To save money, the corporation may use “local couriers, USPS, and the drivers of the Amazon Flex via this method”.

Transportation

Automated loading is easier for Amazon since the corporation employs high-tech robots in its facilities. Amazon depends mostly on UPS and FedEx to transfer goods from fulfilment and outgoing facilities to consumers. Due on the sort of item and how quickly it has to be delivered a variety of transportation options exist. Amazon, for example, launched Prime Now, which enables customers to have their purchases delivered within 2 hours after placing an order on the website. This, however, is dependent on the buyer's location in relation to the storage unit and the method of transportation that are readily accessible. In addition to UPS and FedEx, the corporation has its own branded vehicles, which run mostly between the facilities and fulfilment centres (Hahn 2020). Customers may also expect Amazon Prime Air drone delivery for items weighing less than five pounds in addition to the previously mentioned forms of conveyance. In addition to using cutting-edge technology, the corporation employs some more conventional methods to ensure that its products reach clients, particularly in remote regions. Amazon's distribution system and logistics are made more efficient and effective via the use of these numerous strategies.

Industry 4.0 influence organizations

Based on the many tactics used by Amazon in its supply chain and operations management, it is clear that technology is one of the most important components in assuring the performance of the firms. Procurement is one of the most important factors to consider in the supply chain management process. Amazon, for example, developed a vendor central to assure effective procurement of the numerous items that could not otherwise be manufactured by the organisation. There will be no delays or hiccups in the flow of products and services if such a system is put into place. Even while a firm that manufactures its own products or services is the best choice in most cases, specialising in a key strength is the greatest option in other cases. According the agency cost theory, which emphasises on the delegation of secondary responsibilities to the agents in order for them to concentrate on their areas of strength, this is a cause for worry (Garay-Rondero et al. 2020). The availability of items for clients on the Amazon website is the primary area of contention of the Amazon Corporation.

When it comes to assuring the success of a company's operations and supply chain management, technological development is yet another important factor to consider. In the opinion of Novakova and colleagues, the use of technology, such as the usage of artificial intelligence, is a critical component of assuring strategy success inside the logistics and supply chain management. The usage of development technologies and drones by the Amazon Corporation has been cited as one of the primary factors in the company's growth and expansion. When opposed to other businesses that continue to rely on conventional methods such as human labour, Amazon has guaranteed that effectiveness and efficiency are maintained. Purchases can be processed considerably more quickly and efficiently with the use of technology, while at the same time superfluous costs may be eliminated, resulting in increased earnings.

Figure 4: Industry 4.0 and Sustainable Manufacturing

(Source: futurebridge.com, 2018)

The introduction of innovative resources relies heavily on the formation of cooperative connections between corporate partners when executing operations. According to network theory, the creation of strong linkages among organisations that are interconnected is very important. In the case of something like the Amazon firm, where some of the items offered on its website are purchased from 3rd parties and others are simply put up for auction on the supplier's behalf, this idea plays a critical role in determining how much money the company makes. The establishment of a stable connection helps to eliminate the need for repeated supplier changes, so increasing the efficiency of the business.

This field of industry has undergone a great deal of development and progress since the 1960s, when the supply chain idea was first introduced into society. From the implementation of traditional brick-and-mortar tactics to the use of cutting-edge technology, management and logistics have long been regarded as a critical component of successful corporate operations. Using principles such as e-supply management and e-commerce, firms such as Amazon have expanded and have become the largest online retailer in the world, surpassing even Wal-Mart (Hahn, 2020). While facing several obstacles such as access to customers in remote regions and the inability to maintain secure business connections, Supply & Logistics Management continues to be recognised as a critical component of the organizations operational.

Industry 4.0 influence people in Amazon

In terms of optimising performance via the use of technical breakthroughs in order to provide excellent logistics and supply chain management, the Amazon Corporation is one of the firms that has made significant contributions. This multi-tiered inventory management system does have several advantages, such as practical technology and a well-coordinated transportation system, but it still has a few problems that may be resolved to enhance its effectiveness.

For starters, the corporation is increasingly reliant on transportation couriers such as UPS and FedEx, which has a number of ramifications for the organisation. Based on their findings, they determined that “Amazon paid $37.9 billion in shipping charges in 2017”, comparison to the prior year's $27.7 billion and that this figure has been steadily increasing over time. As a consequence of the company's reliance on transportation couriers, the company's brand image has been harmed to some degree (Hofmann et al. 2019). As a result, expanding the industry's transportation system, which comprises both the prime movers and the vehicles, is the best course of action. It is possible that this step, similar to the introduction of the vendor central, which streamlined the company's operations, may prove to be very important in integrating the firms' supply and logistics systems.

Figure 5: Industry 4.0 in Amazon

(Source: smart-industry.net, 2021)

Another advantage of a co-ordination approach over the co-operation approach now in use is that the organisation may attain a greater level of SCM integration. Transparency will be improved as a result of the information being shared with its suppliers using the most up to date technologies. Because it facilitates the flow of goods and information, inter-organizational solidarity is critical, as the network theory posits (Luthra, & Mangla, 2018). Because the corporation is dealing with accountability concerns as a result of outsourcing certain operations, the construction of a unified massive information technology system might be the key to overcoming these difficulties.

Conclusion

The practise of extrapolating far into the future from current history is dangerous, regardless of whether the history is of invention, affiliations, or monetary instances are being shown. The current manufacturing network, in terms of supply chain advancements, looks to make the operation's technique more straightforward. When it comes to technical developments, innovation may manifest itself in a variety of unexpected ways. Alternatively, and more cynically, its implementation might be limited, limiting the effectiveness of Supply Chain 4.0's deployment to underdeveloped countries and contributing to global wage inequalities.

Recommendations

• There are several companies that have benefited greatly from technology improvements in logistics and supply chain management, such as Amazon.com, which is one of the most successful.

• Some issues remain, however, despite the fact that it has a multi-tiered inventory, highly practical technology, and well-coordinated transport system.

• When it comes to transportation couriers like UPS and FedEx, the organisation tends to depend more heavily on these services. According to statista.com, Amazon paid $37.9 billion in shipping costs last year, compared to $27.7 billion the year before, and has been steadily rising since.

• Dependence on delivery services detracts from the company's brand image to some degree. As a result, the corporation should increase its transportation service, which covers both the prime and the trucks. With this shift, organisations' supply and logistics will be more integrated, much as when vendor central was introduced, which improved the company's operations.

Reference list

Download Samples PDF

Related Sample

- MN623 Cyber Security and Analytics Assignment

- COMP1680 Cloud Computing Coursework Report

- DATA6000 Industry Research Report 4

- MIS609 Data Management and Analytics Report 3

- MBA5006 Managing Organisational Behaviour Assignment

- ACCY902 Forensic Accounting Assignment

- Microservices Architecture Assignment

- HI6025 Accounting Theory and Current Issues Assignment

- CSM80003 Construction Law and Contract Management Assignment

- PRJ5002 Enterprise and Resource Planning Assignment

- COIT20250 Emerging Technologies in E business Assignment

- MGT604 Strategic Management Report 2A

- ENV101 Introduction To Events Assignment

- DATA4900 Innovation and Creativity in Business Analytics Report 4

- MBA5008 Business Research Methods Report 3

- MGT501 Business Environment Report 1

- HI6008 Business Research Project Report

- MRKT20052 Marketing Management and Digital Communication Assignment

- Artificial Nanoparticle Blood Instant Oxygen Boost Report Assignment

- HAS108 Health Assessment

Assignment Services

-

Assignment Writing

-

Academic Writing Services

- HND Assignment Help

- SPSS Assignment Help

- College Assignment Help

- Writing Assignment for University

- Urgent Assignment Help

- Architecture Assignment Help

- Total Assignment Help

- All Assignment Help

- My Assignment Help

- Student Assignment Help

- Instant Assignment Help

- Cheap Assignment Help

- Global Assignment Help

- Write My Assignment

- Do My Assignment

- Solve My Assignment

- Make My Assignment

- Pay for Assignment Help

-

Management

- Management Assignment Help

- Business Management Assignment Help

- Financial Management Assignment Help

- Project Management Assignment Help

- Supply Chain Management Assignment Help

- Operations Management Assignment Help

- Risk Management Assignment Help

- Strategic Management Assignment Help

- Logistics Management Assignment Help

- Global Business Strategy Assignment Help

- Consumer Behavior Assignment Help

- MBA Assignment Help

- Portfolio Management Assignment Help

- Change Management Assignment Help

- Hospitality Management Assignment Help

- Healthcare Management Assignment Help

- Investment Management Assignment Help

- Market Analysis Assignment Help

- Corporate Strategy Assignment Help

- Conflict Management Assignment Help

- Marketing Management Assignment Help

- Strategic Marketing Assignment Help

- CRM Assignment Help

- Marketing Research Assignment Help

- Human Resource Assignment Help

- Business Assignment Help

- Business Development Assignment Help

- Business Statistics Assignment Help

- Business Ethics Assignment Help

- 4p of Marketing Assignment Help

- Pricing Strategy Assignment Help

- Nursing

-

Finance

- Finance Assignment Help

- Do My Finance Assignment For Me

- Financial Accounting Assignment Help

- Behavioral Finance Assignment Help

- Finance Planning Assignment Help

- Personal Finance Assignment Help

- Financial Services Assignment Help

- Forex Assignment Help

- Financial Statement Analysis Assignment Help

- Capital Budgeting Assignment Help

- Financial Reporting Assignment Help

- International Finance Assignment Help

- Business Finance Assignment Help

- Corporate Finance Assignment Help

-

Accounting

- Accounting Assignment Help

- Managerial Accounting Assignment Help

- Taxation Accounting Assignment Help

- Perdisco Assignment Help

- Solve My Accounting Paper

- Business Accounting Assignment Help

- Cost Accounting Assignment Help

- Taxation Assignment Help

- Activity Based Accounting Assignment Help

- Tax Accounting Assignment Help

- Financial Accounting Theory Assignment Help

-

Computer Science and IT

- Operating System Assignment Help

- Data mining Assignment Help

- Robotics Assignment Help

- Computer Network Assignment Help

- Database Assignment Help

- IT Management Assignment Help

- Network Topology Assignment Help

- Data Structure Assignment Help

- Business Intelligence Assignment Help

- Data Flow Diagram Assignment Help

- UML Diagram Assignment Help

- R Studio Assignment Help

-

Law

- Law Assignment Help

- Business Law Assignment Help

- Contract Law Assignment Help

- Tort Law Assignment Help

- Social Media Law Assignment Help

- Criminal Law Assignment Help

- Employment Law Assignment Help

- Taxation Law Assignment Help

- Commercial Law Assignment Help

- Constitutional Law Assignment Help

- Corporate Governance Law Assignment Help

- Environmental Law Assignment Help

- Criminology Assignment Help

- Company Law Assignment Help

- Human Rights Law Assignment Help

- Evidence Law Assignment Help

- Administrative Law Assignment Help

- Enterprise Law Assignment Help

- Migration Law Assignment Help

- Communication Law Assignment Help

- Law and Ethics Assignment Help

- Consumer Law Assignment Help

- Science

- Biology

- Engineering

-

Humanities

- Humanities Assignment Help

- Sociology Assignment Help

- Philosophy Assignment Help

- English Assignment Help

- Geography Assignment Help

- Agroecology Assignment Help

- Psychology Assignment Help

- Social Science Assignment Help

- Public Relations Assignment Help

- Political Science Assignment Help

- Mass Communication Assignment Help

- History Assignment Help

- Cookery Assignment Help

- Auditing

- Mathematics

-

Economics

- Economics Assignment Help

- Managerial Economics Assignment Help

- Econometrics Assignment Help

- Microeconomics Assignment Help

- Business Economics Assignment Help

- Marketing Plan Assignment Help

- Demand Supply Assignment Help

- Comparative Analysis Assignment Help

- Health Economics Assignment Help

- Macroeconomics Assignment Help

- Political Economics Assignment Help

- International Economics Assignments Help

-

Academic Writing Services

-

Essay Writing

- Essay Help

- Essay Writing Help

- Essay Help Online

- Online Custom Essay Help

- Descriptive Essay Help

- Help With MBA Essays

- Essay Writing Service

- Essay Writer For Australia

- Essay Outline Help

- illustration Essay Help

- Response Essay Writing Help

- Professional Essay Writers

- Custom Essay Help

- English Essay Writing Help

- Essay Homework Help

- Literature Essay Help

- Scholarship Essay Help

- Research Essay Help

- History Essay Help

- MBA Essay Help

- Plagiarism Free Essays

- Writing Essay Papers

- Write My Essay Help

- Need Help Writing Essay

- Help Writing Scholarship Essay

- Help Writing a Narrative Essay

- Best Essay Writing Service Canada

-

Dissertation

- Biology Dissertation Help

- Academic Dissertation Help

- Nursing Dissertation Help

- Dissertation Help Online

- MATLAB Dissertation Help

- Doctoral Dissertation Help

- Geography Dissertation Help

- Architecture Dissertation Help

- Statistics Dissertation Help

- Sociology Dissertation Help

- English Dissertation Help

- Law Dissertation Help

- Dissertation Proofreading Services

- Cheap Dissertation Help

- Dissertation Writing Help

- Marketing Dissertation Help

- Programming

-

Case Study

- Write Case Study For Me

- Business Law Case Study Help

- Civil Law Case Study Help

- Marketing Case Study Help

- Nursing Case Study Help

- Case Study Writing Services

- History Case Study help

- Amazon Case Study Help

- Apple Case Study Help

- Case Study Assignment Help

- ZARA Case Study Assignment Help

- IKEA Case Study Assignment Help

- Zappos Case Study Assignment Help

- Tesla Case Study Assignment Help

- Flipkart Case Study Assignment Help

- Contract Law Case Study Assignments Help

- Business Ethics Case Study Assignment Help

- Nike SWOT Analysis Case Study Assignment Help

- Coursework

- Thesis Writing

- CDR

- Research

.png)

~5.png)

.png)

~1.png)

.png)